Our Story

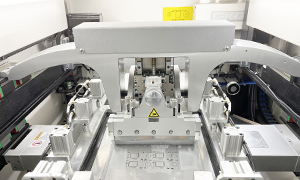

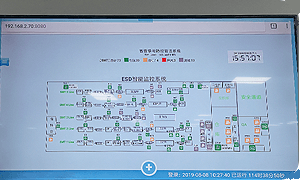

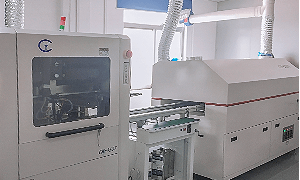

Shenzhen Bocheng Technology Co.,Ltd has been established in in 2015, We are a professional PCB fabrication&PCB assembly factory, providing services of PCB manufacturing,PCB Assembly, electronic parts sourcing,functional test for our worldwide customers. We have 10 high speed SMT production lines and 4 through hole pcb assembly lines and more than 180 skilled workers to meet our customers’various kinds of needs.

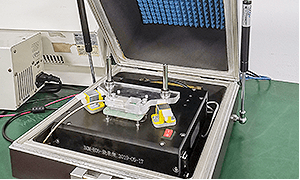

Bocheng offers DFM (Design for Manufacturing) checking services for all orders. This service is appropriate for PCBA prototypes in addition to low and medium volume manufacturing runs. We verify every element of your files, including BOM (Bill of Materials) and Gerber files, so that you can adjust your PCB design prior to manufacturing, thereby saving you substantial time and money and preventing wasteful prototyping assembly process repeats.

Bocheng also collaborates with well-known producers of electronic components from around the world or their first class agents to ensure that the components are authentic, affordable, and of high quality. We also have more than ten years of in-depth research into China’s local electronic parts manufacturing industry, which has enabled us to identify the most appropriate and cost-effective substitutes for our customers.

You design it we assembly it,Bocheng will be your solid partner whether in PCB Fabrication&PCB assembly!